Teaching & Learning Engagement in Architecture & Interior Architecture Programs

School of Architecture & Built Environment, UCSI University

Extruded deck in order for anchovy boat to stop by. Also use for unload anchovy and deliver to factory area.

Where the workers rest. Here also combine the fridge for storing export anchovy and temporary storage when anchovy are unloaded from boat.

Podium

The connection between factory and the sea. The drying activities also happen at here.

Decking

Large storage area including ice fridge storage and dry storage. Office are usually located in this zone too.

Storage and Office

Where the sorting mechine locate and where most sorting and packaging process happen.

Factory

The carpark area where connect to traffic and also play role as loading bay. In anchovy happening season, here will also used for drying area.

Carpark

A mordern way to dry anchovy, require small area but able to fullfill same amount of drying task as decking area.

Greenhouse

Boat & Out Deck

Seine-haul Fishing

The Anchovy is carefully chosen and dried to perfection before being prepacked in our factory for optimal quality. With various sizes available and well packed ready to outsources.

Pouring Net

After locating the anchovies, the entire crew stands poised at the bow of the boat before releasing the net into the sea. The net remains submerged for 40 to 60 minutes before being pull up and it takes roughly 7 to 9 people to pull up the net with the assist of pulley.

Pouring Icon Rings

The iron rings weighted 5kg and 10kg are pour to the sea one by one.

Rolling Up

The Anchovy is carefully chosen and dried to perfection before being prepacked in our factory for optimal quality. With various sizes available and well packed ready to outsources.

Harvesting

The Anchovy is carefully chosen and dried to perfection before being prepacked in our factory for optimal quality. With various sizes available and well packed ready to outsources.

Pouring Net

A specific net will be used to scoop the anchovies from the fishing net and put into a cleaning tank to wash off unwanted waste and sort out bigger fishes.

Pouring Icon Rings

The iron rings weighted 5kg and 10kg are pour to the sea one by one.

Rolling Up

The Anchovy is carefully chosen and dried to perfection before being prepacked in our factory for optimal quality. With various sizes available and well packed ready to outsources.

Boiling

The Anchovy is carefully chosen and dried to perfection before being prepacked in our factory for optimal quality. With various sizes available and well packed ready to outsources.

Scooping

A specific net will be used to scoop the anchovies from the fishing net and put into a cleaning tank to wash off unwanted waste and sort out bigger fishes.

Placing

The Anchovy is carefully chosen and dried to perfection before being prepacked in our factory for optimal quality. With various sizes available and well packed ready to outsources.

Boiling

4 workers will be managing the boiling process and the anchovies will then be boiled in the water for 3--5 minutes.

Drying

The Anchovy is carefully chosen and dried to perfection before being prepacked in our factory for optimal quality. With various sizes available and well packed ready to outsources.

Harvesting

Collect the dried anchovies. The anchovy is gradually collected while pulling the net to assemble the anchovy into one point. Then flip the anchovy into the Lua (basket) in front.

Flipping

Flipping the anchovies using bamboo rake during the drying process to prevent clumped anchovies which will affect the level of moisture, indeed affact the taste and texture.

Spreading & Flattening

One worker drags the net from an orange container placed near the owner's office all along to the end of the deck for anchovy drying,Two workers at each corner will pull the net to flatten the net for the anchovy drying process

Hitting, Rotating & Spreading

Flipping the anchovies using bamboo rake during the drying process to prevent clumped anchovies which will affect the level of moisture, indeed affact the taste and texture.

Machine Soring

The Anchovy is carefully chosen and dried to perfection before being prepacked in our factory for optimal quality. With various sizes available and well packed ready to outsources.

Replacing

When the Lua is fulled of anchovy, the worker will need to replace an empty Lua. It is around 20 min to replace one Lua.

Preparing

A lua of anchovy will taken out from chiller and placed behind the machine.

Pouring

The worker slowly pour the anchovy using hands into machine.

Checking

One worker uses their hand to hit the anchovy that trapped on sifting screen.

.png)

.png)

.png)

.png)

.png)

Manual Sortiong

The Anchovy is carefully chosen and dried to perfection before being prepacked in our factory for optimal quality. With various sizes available and well packed ready to outsources.

Sieving

Sieving anchovies to remove extra dust from the final product. First, they will scoop the anchovies and place them to basket, by using the hollow of bamboo basket, the dust and containinated substances will fall.

Hand Sorting

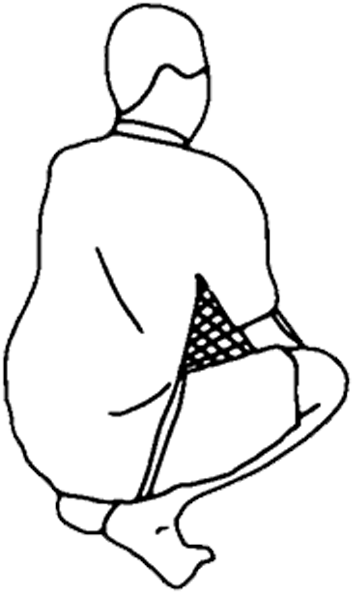

Preparing for sorting anchovies manually, sorting the anchovies manually. 3 workers in each table to manually sort 12.5kg of anchov

Cleaning

The accumulated dust on floor will be spoon up and collect on a plastic.

Selecting

The smallest size anchovy which normally are Ikan Mata Biru will fall on floor, then the worker will pull out the cloth placed below the machine for sorting out the bigger size anchovy.

Loose Packaging

The Anchovy is carefully chosen and dried to perfection before being prepacked in our factory for optimal quality. With various sizes available and well packed ready to outsources.

Weighting

Packing the sealed dried anchovies into a huge plastic bag then start weighing. Measure the weight of one pack of anchovies using the weighing machine. It took one worker to do the measurement. It contains 25 kg per pack.

Packaging

Two workers pour the spread anchovies from ground by folding the plastic sheet into another bag. After the bag is weighted, tighten up the 25kg prepack anchovies with thread.

Pouring and Tightening

Before transfer the prepack anchovy, should correct the labeling using alcohol and cloth. Once the label is corrected, put the package into another sack to refrain leakage and better quality while transferring to the cargo ship at the corner of the deck. Then, place it to the upper level of chiller to seperate from end product and post-end product.

Pre-Packaging

The Anchovy is carefully chosen and dried to perfection before being prepacked in our factory for optimal quality. With various sizes available and well packed ready to outsources.

Pouring and Tightening

Before transfer the prepack anchovy, should correct the labeling using alcohol and cloth. Once the label is corrected, put the package into another sack to refrain leakage and better quality while transferring to cargo ship at the corner of the deck. Then, place it to the upper level of chiller to seperate from end product and post-end product.

Spreading and Weigthing

Packing the sealed dried anchovies into a huge plastic bag then start weighing. Measure the weight of one pack of anchovies using the weighing machine. It took one worker to do the measurement. It contains 25 kg per pack.

Transferring

Before transfer the prepack anchovy, should correct the labeling using alcohol and cloth. Once the label is corrected, put the package into another sack to refrain leakage and better quality while transferring to the cargo ship at the corner of the deck. Then, place it to the upper level of chiller to seperate from end product and post-end product.

Who are the people behind each and every complex flow of the Anchovy Trade? As a verbal study and documentation, interview methodology can provide a more comprehensive acknowledgements towards these faces.